Cricket is more than just a sport in India; it’s a passion that unites people from every corner of the country. From street matches to international stadiums, cricket holds a special place in the hearts of millions of fans. Central to the game of cricket is one essential piece of equipment – the cricket bat. In this blog, we’ll explore how a bat is made, the different types of wood used, and why the bat from India holds a unique place in the world of cricket.

BUY BEST QUALITY CRICKET BATS FROM OUR WEBSITE WWW.VINOXSPORTS.COM

The Importance of the Cricket Bat in India

The cricket bat is the fundamental tool of the game. It allows players to score runs, defend against deliveries, and execute spectacular shots that often lead to game-changing moments. In India, the cricket bat isn’t just a piece of sporting equipment; it’s a symbol of excellence, performance, and craftsmanship. Whether it’s a young player making their debut in the local park or a seasoned cricketer playing in the IPL, the choice of cricket bat plays a crucial role in their performance.

The Origin of the Cricket Bat

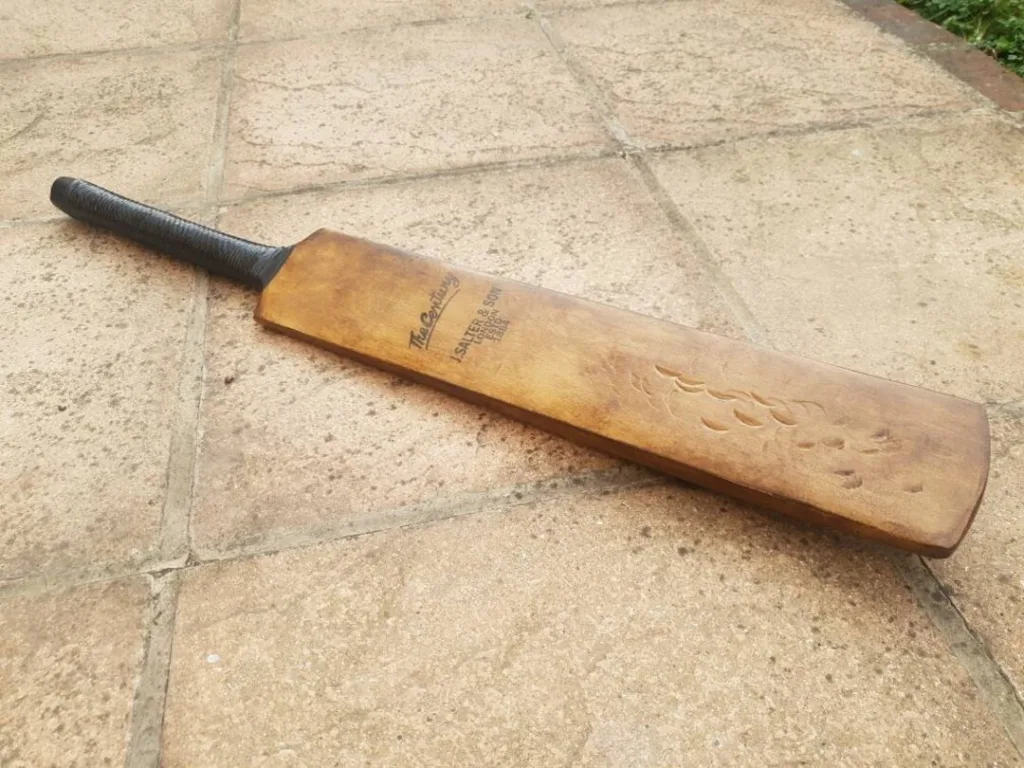

The cricket bat has evolved over centuries. Historically, early versions of the bat were simply pieces of wood with no particular shape or design. As the game of cricket evolved, so did the cricket bat. In India, the craft of making cricket bats dates back to the 19th century. The growth of cricket in India has given rise to some of the best bat makers in the world, and the demand for quality cricket bats in India has never been higher.

Types of Wood Used in Cricket Bat Production

One of the key factors that determine the quality of a cricket bat is the wood used in its creation. The majority of cricket bats are made from two types of wood: willow and poplar. However, willow is the wood of choice for professional-level cricket bats due to its durability and ability to withstand impact.

English Willow

English willow, which is primarily grown in the UK, is considered the best wood for making high-quality cricket bats. It is lightweight, flexible, and has an excellent balance between strength and power. The unique grain structure of English willow helps absorb the shock of hitting the ball, giving it a “sweet spot” that ensures maximum power and control during batting.

In India, there is a growing demand for English willow bats, and they are considered the gold standard by professional cricketers. Cricket bats made from English willow are often used by international players in the Indian Premier League (IPL) and other prestigious cricket tournaments.

Kashmir Willow

While English willow is the preferred choice for high-end cricket bats, Kashmir willow is a popular alternative. Grown in the Kashmir region of India, Kashmir willow is denser and slightly heavier than English willow, but it still provides a good performance at a more affordable price. Kashmir willow cricket bats are widely used by amateur cricketers and are a popular choice in India due to their availability and cost-effectiveness.

The Kashmir willow is more abundant, which makes it easier for manufacturers to source, but the grain structure is not as fine as English willow. Nevertheless, the cricket bat made from Kashmir willow offers excellent performance and durability, which is why it is highly favored in local leagues and regional tournaments.

The Crafting Process of a Cricket Bat

Creating a high-quality cricket bat is a time-consuming and intricate process. The process requires skill, precision, and attention to detail. A bat typically takes several hours to complete, and only the finest artisans can create a bat that meets international standards.

Step 1: Selecting the Wood

The first step in making a cricket bat is selecting the right piece of wood. The wood needs to be free of knots, cracks, and other imperfections. This ensures the bat will be strong, durable, and balanced. The wood is carefully inspected for its grain structure and weight. A bat with straight, clean grains is preferred, as it ensures more strength and power.

Step 2: Shaping the Bat

Once the right wood is chosen, the bat maker begins the process of shaping the bat. This is done using specialized tools such as chisels, planes, and saws. The bat is shaped into the iconic blade and handle design that we all recognize. The thickness of the blade and the curve of the back are meticulously crafted to give the bat the correct balance and weight distribution.

Step 3: The Handle

The handle of the cricket bat is made from a different type of wood – typically cane – for flexibility and shock absorption. The handle is attached to the blade using a combination of glue and binding. This allows the bat to have a proper grip, which gives the batter control over their strokes.

Step 4: Polishing and Finishing

After the cricket bat has been shaped, it undergoes a final polishing process. The wood is sanded to create a smooth finish, and sometimes a protective coating is applied to enhance the bat’s durability. The finishing process also includes attaching the rubber grip to the handle and adding any additional branding or logos.

The Role of Cricket Bat Manufacturers in India

India is home to some of the world’s most renowned cricket bat manufacturers. Brands like Vinox, SG, Kookaburra, and MRF have been making cricket bats for decades and have earned international recognition. These manufacturers combine traditional craftsmanship with modern techniques to produce bats that meet the standards of professional cricket.

Indian manufacturers are particularly famous for their high-quality Kashmir willow bats, which are used by countless cricketers in domestic and international matches. However, several manufacturers also import English willow to meet the demand for top-tier cricket bats.

Why the Cricket Bat Matters to Indian Cricketers

In India, a cricket bat is often more than just a piece of sporting equipment. For many aspiring cricketers, their first bat is a cherished possession that symbolizes their dreams of becoming a cricketing legend. A bat is a connection to the sport’s rich legacy, and it has the potential to create unforgettable moments on the field.

The right cricket bat can make a significant difference in a player’s performance. For professional cricketers, the quality of the bat directly impacts the power of their shots and the consistency of their performance. Bat manufacturers in India are aware of the demands of the game and continually innovate to provide cricketers with bats that offer superior performance.

The bat is much more than just a piece of equipment in India. It is an integral part of the cricketing culture, representing skill, tradition, and craftsmanship. The process of creating a bat is an art form. And the choice of wood is critical in ensuring that the bat performs at its best. Whether it’s an English willow bat used by professionals or a Kashmir willow bat preferred by amateurs. The bat plays an essential role in the game of cricket in India.

As the demand for quality cricket bats continues to grow. The craftsmanship of Indian bat makers remains as important as ever. Ensuring that every bat, whether used in the streets of Mumbai or the stadiums of Delhi. Lives up to the expectations of the cricket-loving nation.

No products in the cart.

No products in the cart.